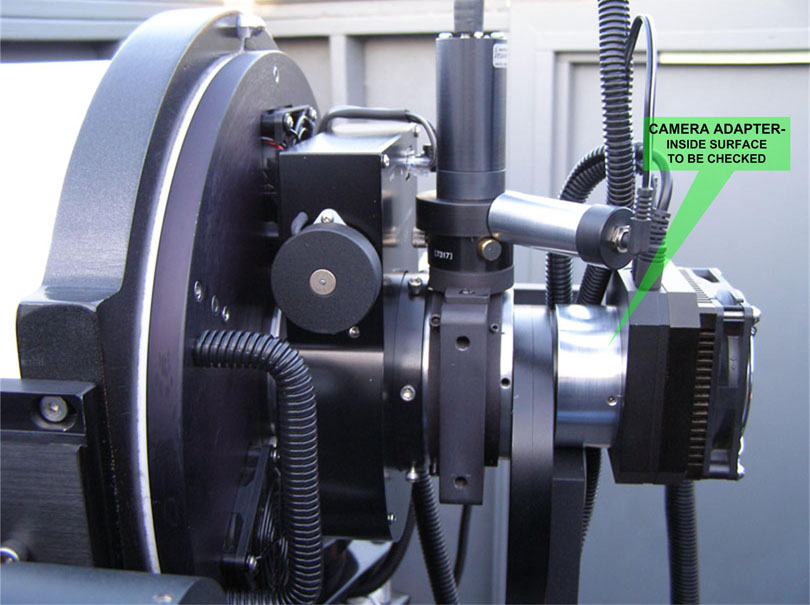

Image Train to be Checked The set screws that were adjusted were on the back of the "Pyxis Rotator" and on the front & back of the "Monster MOAG." |

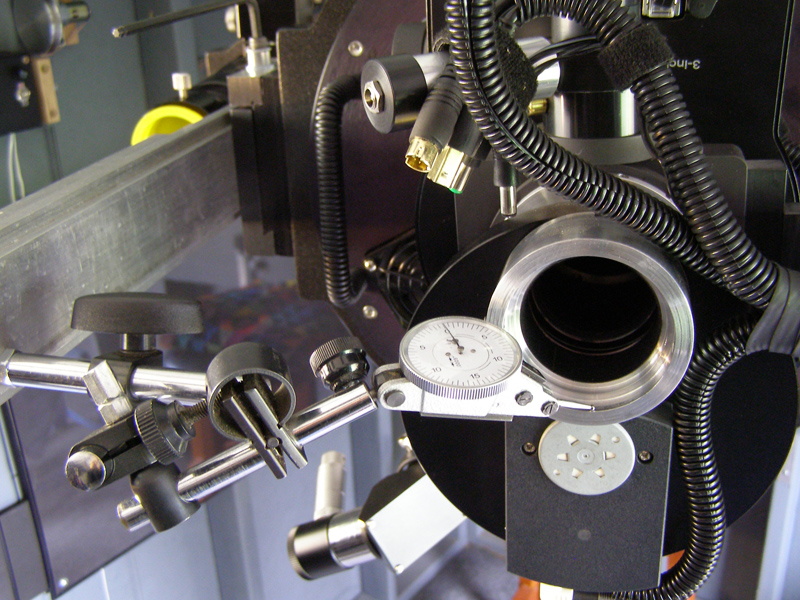

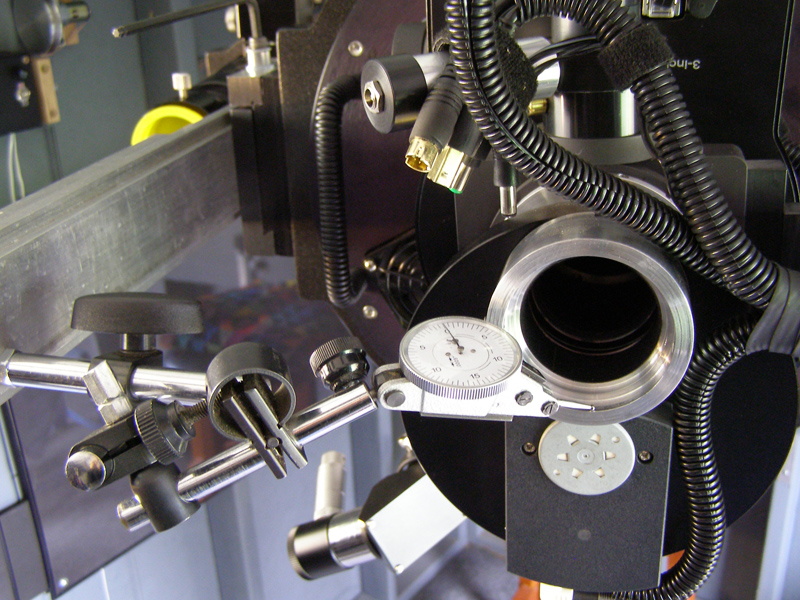

The Setup for Checking TIR I used an aluminum bar attached to a dovetail bracket with the dial indicator assembly mounted at the opposite end. This provides a very solid base for accurate readings of the camera mount surface as it rotates a full 360 degrees. |

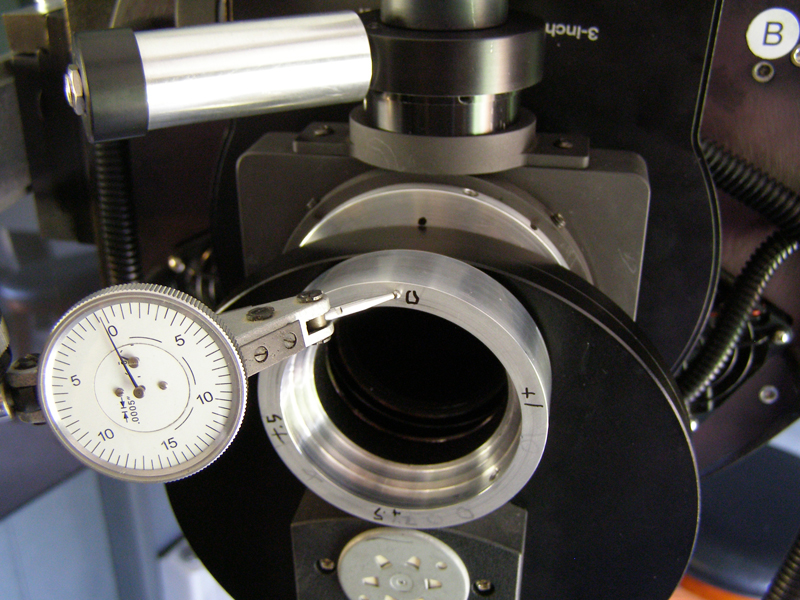

Checking Camera Mount Surface Parallelism Some components in the image train can easily throw-out the camrera mount surface. Here the setup is used for checking the surface while rotating a full 360 deg. In this case the external "Filter Wheel" was not flat and parallel. I needed to shim under the camera adapter with small strips of clear tape, and was able to achieve a total run out of.0005". |

Method for Checking Image Train Run Out The following set up was used for checking and adjusting the runout on the image train when rotating the "Pyxis Rotator" a full 360 degrees. Initially the Total Indicator Runout (TIR) was .040". This really caused the Tak Dot to move off center quite a lot when rotating the Pyxis to different Position Angles. The major culprit was the Filter Wheel; scope side and camera side threads were severely offset. After adjusting various adapter set screws from the back of the Pyxis to the Camera I was able to reduce this runout down to only .002" TIR. "The Tak Dot, now stays nicely centered." This setup may also be used for checking the camera mount surface for "parallelism." A very important issue when trying to achieve uniform focus across larger size CCD chips.

|